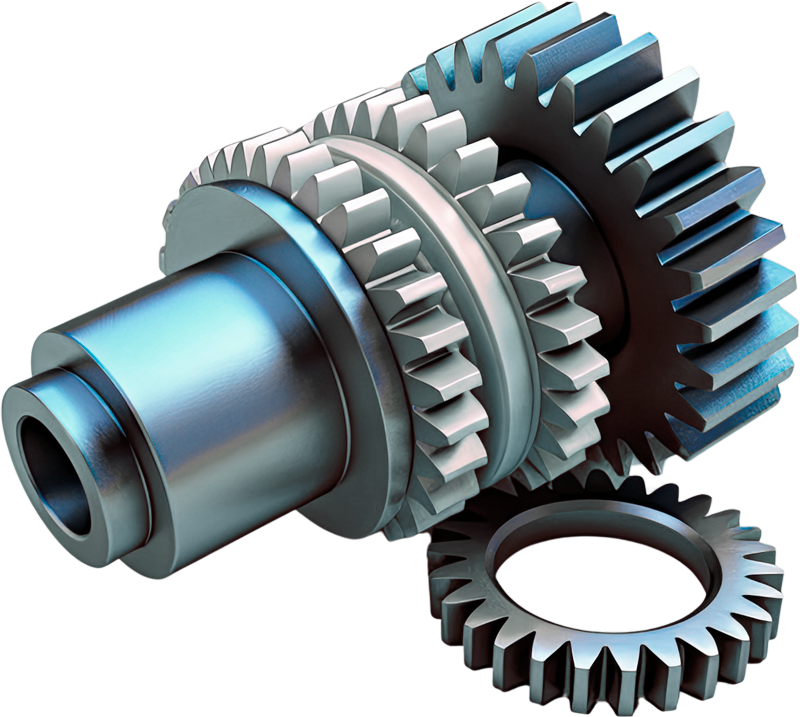

Contract grinding

fabrication and assembly of mechanical parts.

A history of quality

Specializing in grinding mechanical parts for 40 years.

%

Ground mechanical parts, from drawing to assembly.

We have specialized in grinding small and medium-sized mechanical parts since 1986.

The evolution in the industry

Thanks also to the cooperation with historical and certified partners, we are able to offer machining on a wide range of complex mechanical parts.

A global service

Services

High accuracy

Measurement

Grinding

Accessory services

Turning and milling

Quality and dimensional controls

Air-conditioned Control Room

Our Climate Control Room represents the beating heart of our dimensional inspections. Equipped with a climate-controlled environment, we ensure optimal conditions for performing accurate and reliable measurements.

State-of-the-art instrumentation, certified for each type of dimensional inspection, ensures accurate control of heights, internal and external diameters, taper and ovality, flatness and roughness, as well as detailed surface checks such as radii and chamfers.

Certified Technology

At O.M.P. Grinding, we invest in the most advanced technology for dimensional inspection.

To stay abreast of the increasingly stringent tolerances required by customers, O.M.P. believes in continuous innovation in inspection technology, operates and maintains all its measuring instruments, even the simplest ones, under periodic inspection.

Custom Workmanship

Our flexibility in our approach to measurements allows us to adapt to the complexities of each component, ensuring satisfactory results every time.

Certified Collaboration

Our network of partnerships enables us to offer a full range of mechanical measurements that our customers can rely on.